Take charge of any engineering challenge.

Embrace emerging technologies, extend existing systems, and do anything in between. With flexible, open technologies, you can be ready for inevitable change.

Facility Integrity Management (FIM)

The production plant has many equipment to facilitate the production process, the vessels, columns, boilers, exchangers, piping, valves, instruments, pumps, motors…the equipment that appears in the process engineering flow scheme (PEFS) and process and piping instrument diagrams (P&ID). The integrity of these equipment ensures production can be carried out in a sustainably safe and economical way. Primalux provides consultancy services in this area and can be combined with a flexible WEB based system called i.AIM® to perpetuate the FIM methodology in a graphically transparent manner. The company may already have existing capable systems that cover different aspects of FIM, in this case an interface is setup to allow for data exchange between the various system.

i.ENGINEER | i.INSPECT | i.DOCUMENT | i.RISK | i.COMPLY

Structural Integrity Management (SIM)

The production facility equipment will need structural supports or platforms to be installed on. Platforms will additionally have a subsea component. Deterioration in the structural element will cause major catastrophic loss in terms of life, production, environment and reputation. As such the integrity of the structure must not be overlooked. Primalux provides consultation and has a specialised i.AIM® system configuration for this engineering discipline. The system also has interfaces to work management systems like SAP, process monitoring systems like PI and subsea ROV.

Pipeline Integrity Management (PIM)

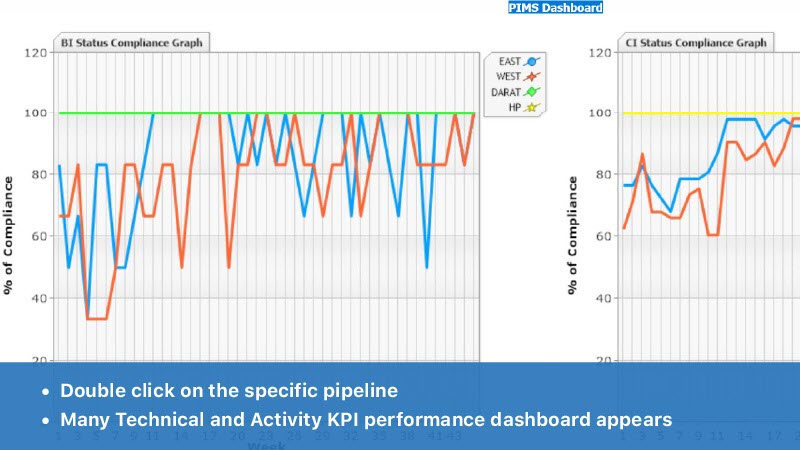

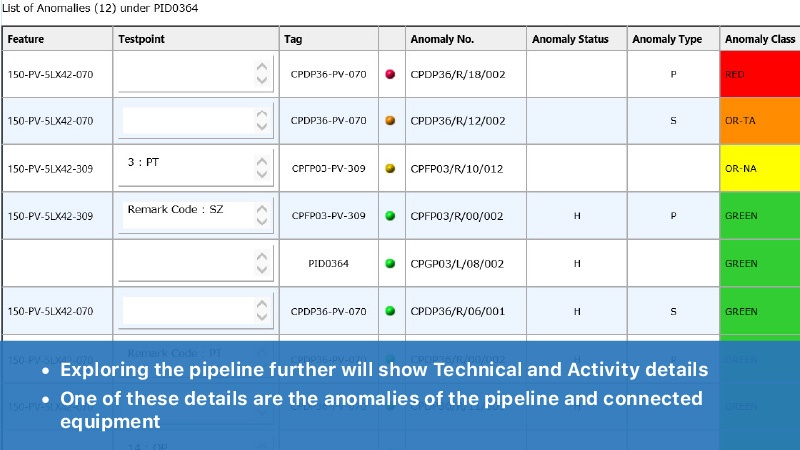

Pipeline Integrity Management is not just the integrity management of the long cylindrical pipe, so the pipeline equipment system must be viewed as a more than a pipeline, it has launcher, receiver, valves, emergency devices, cathodic protection system, inhibition system… all the equipment between the source and final destination including tie ins. Since it can cross many boundaries, local authority governance will add to the expected integrity management standards, and there are company risk management standards and procedures too. This means the pipeline integrity management activities will have to be monitored with the respective technical integrity management. Due to this complexity many companies have endless excel sheets managing all the different aspects of PIM, these excel sheets only make sense to the respective engineers. Once the engineer leaves so does all the valuable data. Primalux provides consultancy services to help unify the PIM view so the multitude of activities and required standards can synergized. Along side the i.AIM® PIM solution, the accomplished work can be perpetuated and even further fine tuned to make sense of all the different integrity statuses.

Tank Integrity Management (TIM)

The raw material or product must be stored in large storage tanks before it is shipped out. The integrity of these storage tank facilities has to be maintained to ensure a smooth supply of raw material or smooth shipment of product. These storage tanks being the size of buildings that contain fluid or gas, will have structural issues and pressure retention issues. The equipment that help ensure safe operations including the access ladder, bund wall, internal equipment… all need to be checked and maintained; the storage tank must be viewed as a system. As such the storage tank is not just the metal walls, roof and bottom, it is all the equipment needed to ensure safe operations of the storage tank, including the activities that need to be done on time. Local authorities and company standards will also impact the required integrity management standards. Primalux has consultancy services to help synergize all these different aspects of TIM. Combined with the i.AIM® TIM solution, the accomplished work can be perpetuated and even further fine tuned to make sense of all the different integrity statuses.

Turnaround Integrity Management (TAIM)

Equipment eventually will suffer degradation and maintenance is inevitable, instead of dealing with equipment one by one, a campaign is planned to rectify multiple issues all at once and possibly further enhance the production process with some further redesign. For this to happen planning occurs years in advance for the turnaround. Furthermore, what is done and not done in the current turnaround will affect the subsequent turnarounds. So, management of the turnaround is very important for minimal disruption to production. There are many activities to manage, required manpower, logistics, catering, equipment, maintenance equipment, special chemicals… all these become special activity management points to check on with their respective quality management check list. So, it is not just about being on time, but the required quantity and quality is available at the right time. Choke points can develop when events are not sequenced properly, or unexpected issues turn up. This focuses on management of turnaround activities, presenting the correct check sheets and required documentation, photos and drawings at the correct time. Primalux also has a TAIM system with Android or IOS tablets that can quickly feed results back, so up to date activity statuses with quantity and quality are known, so the next step decisions can be informed and made quickly.Fully optimizing the time and resources used in the turnaround. TAIM also has interfaces to work order management systems like SAP and corporate planning tools like Primavera.

i.ENGINEER | i.INSPECT | i.COMPLY | i.PLAN

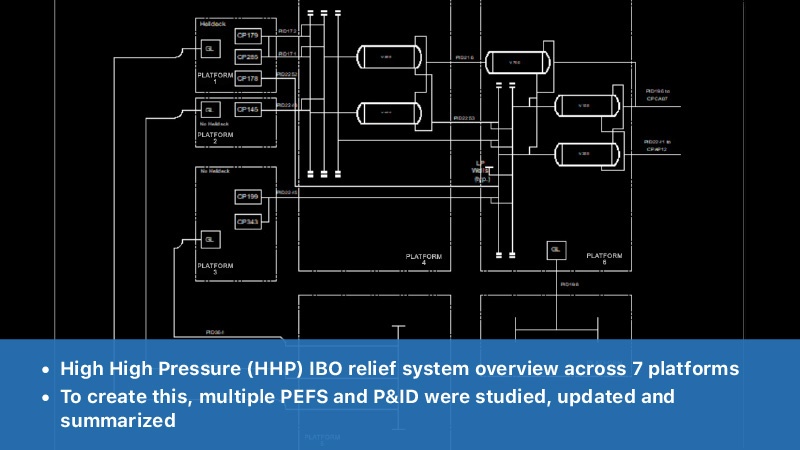

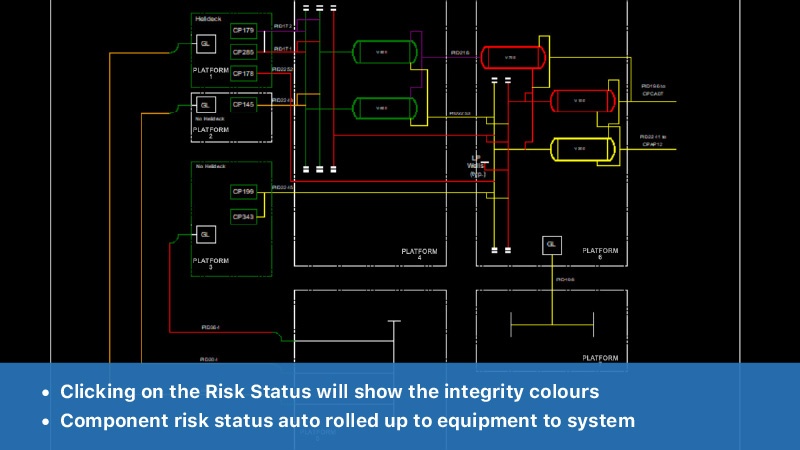

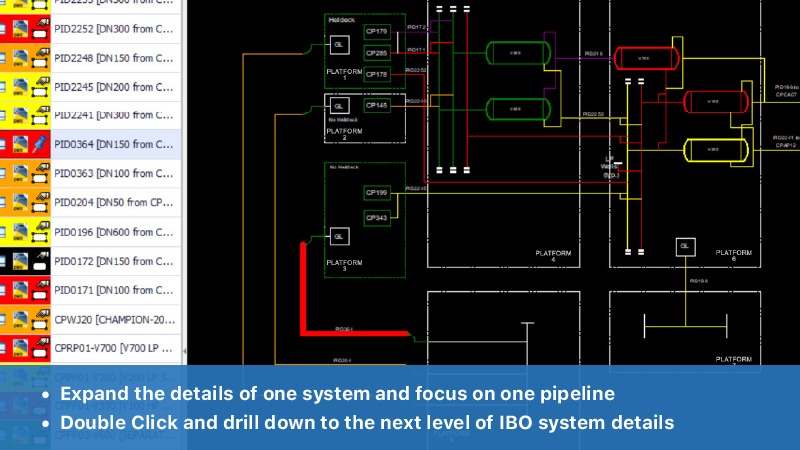

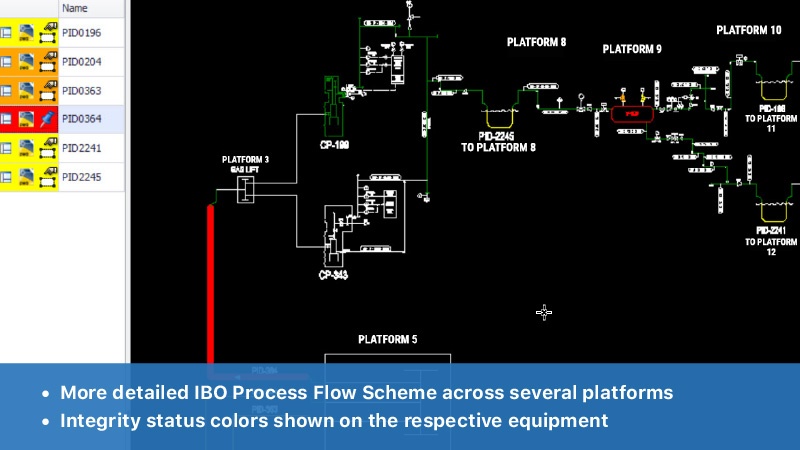

Internal Blowout Management

Internal Blowout management ensures the well and hence reservoir of gas and/or oil is producing safely. The system tracks the relief system from the subsea or subsurface to the final venting of the pressure. Since there maybe condensate in the relief system, it will be separated to be fed back into the production process. This complicates the view of separating IBO systems and production process systems. Typically, it is all entangled in the Process Flow Schemes (PFS), Process Engineering Flow Schemes (PEFS) and Piping and Instrument Diagrams (P&ID). Since a well or reservoir can have a few IBOs, it can spread across a few platforms or production stations. As such it becomes difficult to trace the integrity status of one IBO system, let alone multiple IBO systems spanning many areas.

Primalux looks through all the inspection reports, photographs and drawings, then summarizes the information into different simplified focused views of the IBO system; including the relevant equipment and their respective pressure regimes. Each layered view will reveal more detail of the IBO system. The anomalies found will then relate to the equipment in the specific IBO system, and hence reflect the IBO system integrity status. This is a service combined with the i.AIM® system to form a solution.

i.ENGINEER | i.INSPECT | i.COMPLY | i.INTERFACE | i.DOCUMENT

3rd Party Interfaces

Primalux provides consultancy services for other product interfaces, this is typically in relation to i.AIM® i.INTERFACE module. The interface module is the middleman to provide connection between different data hierarchies and naming conventions. The timing for the data exchanges also needs to be set. Different reports are generated during different stages of the implementation. The initial stage is about data quality and consistency of the provided data. Once it is imported into the system, and the analysis begins, results need to be vetted and checked before it is passed on, for example corrosion rates from wall thickness results. Finally when the system is in operational phase, system sporadic mis-synchronization (different systems upgrade or shutdown) reports are generated. Primalux provides consultancy to investigate the issues and can provide a middleware to extend corporate system capabilities. This is not just between corporate management systems, inspection tools and test certification machines are also part of Primalux interface capabilities.

Facility

Facility Integrity Management (FIM)

The production plant has many equipment to facilitate the production process, the vessels, columns, boilers, exchangers, piping, valves, instruments, pumps, motors…the equipment that appears in the process engineering flow scheme (PEFS) and process and piping instrument diagrams (P&ID). The integrity of these equipment ensures production can be carried out in a sustainably safe and economical way. Primalux provides consultancy services in this area and can be combined with a flexible WEB based system called i.AIM® to perpetuate the FIM methodology in a graphically transparent manner. The company may already have existing capable systems that cover different aspects of FIM, in this case an interface is setup to allow for data exchange between the various system.

i.ENGINEER | i.INSPECT | i.DOCUMENT | i.RISK | i.COMPLY

Structural

Structural Integrity Management (SIM)

The production facility equipment will need structural supports or platforms to be installed on. Platforms will additionally have a subsea component. Deterioration in the structural element will cause major catastrophic loss in terms of life, production, environment and reputation. As such the integrity of the structure must not be overlooked. Primalux provides consultation and has a specialised i.AIM® system configuration for this engineering discipline. The system also has interfaces to work management systems like SAP, process monitoring systems like PI and subsea ROV.

Pipeline

Pipeline Integrity Management (PIM)

Pipeline Integrity Management is not just the integrity management of the long cylindrical pipe, so the pipeline equipment system must be viewed as a more than a pipeline, it has launcher, receiver, valves, emergency devices, cathodic protection system, inhibition system… all the equipment between the source and final destination including tie ins. Since it can cross many boundaries, local authority governance will add to the expected integrity management standards, and there are company risk management standards and procedures too. This means the pipeline integrity management activities will have to be monitored with the respective technical integrity management. Due to this complexity many companies have endless excel sheets managing all the different aspects of PIM, these excel sheets only make sense to the respective engineers. Once the engineer leaves so does all the valuable data. Primalux provides consultancy services to help unify the PIM view so the multitude of activities and required standards can synergized. Along side the i.AIM® PIM solution, the accomplished work can be perpetuated and even further fine tuned to make sense of all the different integrity statuses.

Tank

Tank Integrity Management (TIM)

The raw material or product must be stored in large storage tanks before it is shipped out. The integrity of these storage tank facilities has to be maintained to ensure a smooth supply of raw material or smooth shipment of product. These storage tanks being the size of buildings that contain fluid or gas, will have structural issues and pressure retention issues. The equipment that help ensure safe operations including the access ladder, bund wall, internal equipment… all need to be checked and maintained; the storage tank must be viewed as a system. As such the storage tank is not just the metal walls, roof and bottom, it is all the equipment needed to ensure safe operations of the storage tank, including the activities that need to be done on time. Local authorities and company standards will also impact the required integrity management standards. Primalux has consultancy services to help synergize all these different aspects of TIM. Combined with the i.AIM® TIM solution, the accomplished work can be perpetuated and even further fine tuned to make sense of all the different integrity statuses.

Turnaround

Turnaround Integrity Management (TAIM)

Equipment eventually will suffer degradation and maintenance is inevitable, instead of dealing with equipment one by one, a campaign is planned to rectify multiple issues all at once and possibly further enhance the production process with some further redesign. For this to happen planning occurs years in advance for the turnaround. Furthermore, what is done and not done in the current turnaround will affect the subsequent turnarounds. So, management of the turnaround is very important for minimal disruption to production. There are many activities to manage, required manpower, logistics, catering, equipment, maintenance equipment, special chemicals… all these become special activity management points to check on with their respective quality management check list. So, it is not just about being on time, but the required quantity and quality is available at the right time. Choke points can develop when events are not sequenced properly, or unexpected issues turn up. This focuses on management of turnaround activities, presenting the correct check sheets and required documentation, photos and drawings at the correct time. Primalux also has a TAIM system with Android or IOS tablets that can quickly feed results back, so up to date activity statuses with quantity and quality are known, so the next step decisions can be informed and made quickly.Fully optimizing the time and resources used in the turnaround. TAIM also has interfaces to work order management systems like SAP and corporate planning tools like Primavera.

i.ENGINEER | i.INSPECT | i.COMPLY | i.PLAN

IBO

Internal Blowout Management

Internal Blowout management ensures the well and hence reservoir of gas and/or oil is producing safely. The system tracks the relief system from the subsea or subsurface to the final venting of the pressure. Since there maybe condensate in the relief system, it will be separated to be fed back into the production process. This complicates the view of separating IBO systems and production process systems. Typically, it is all entangled in the Process Flow Schemes (PFS), Process Engineering Flow Schemes (PEFS) and Piping and Instrument Diagrams (P&ID). Since a well or reservoir can have a few IBOs, it can spread across a few platforms or production stations. As such it becomes difficult to trace the integrity status of one IBO system, let alone multiple IBO systems spanning many areas.

Primalux looks through all the inspection reports, photographs and drawings, then summarizes the information into different simplified focused views of the IBO system; including the relevant equipment and their respective pressure regimes. Each layered view will reveal more detail of the IBO system. The anomalies found will then relate to the equipment in the specific IBO system, and hence reflect the IBO system integrity status. This is a service combined with the i.AIM® system to form a solution.

i.ENGINEER | i.INSPECT | i.COMPLY | i.INTERFACE | i.DOCUMENT

3rd Party

3rd Party Interfaces

Primalux provides consultancy services for other product interfaces, this is typically in relation to i.AIM® i.INTERFACE module. The interface module is the middleman to provide connection between different data hierarchies and naming conventions. The timing for the data exchanges also needs to be set. Different reports are generated during different stages of the implementation. The initial stage is about data quality and consistency of the provided data. Once it is imported into the system, and the analysis begins, results need to be vetted and checked before it is passed on, for example corrosion rates from wall thickness results. Finally when the system is in operational phase, system sporadic mis-synchronization (different systems upgrade or shutdown) reports are generated. Primalux provides consultancy to investigate the issues and can provide a middleware to extend corporate system capabilities. This is not just between corporate management systems, inspection tools and test certification machines are also part of Primalux interface capabilities.